Avoid equipment

downtime

Reduce maintenance

costs

Improve maintenance scheduling

The Importance of Vibration Analysis

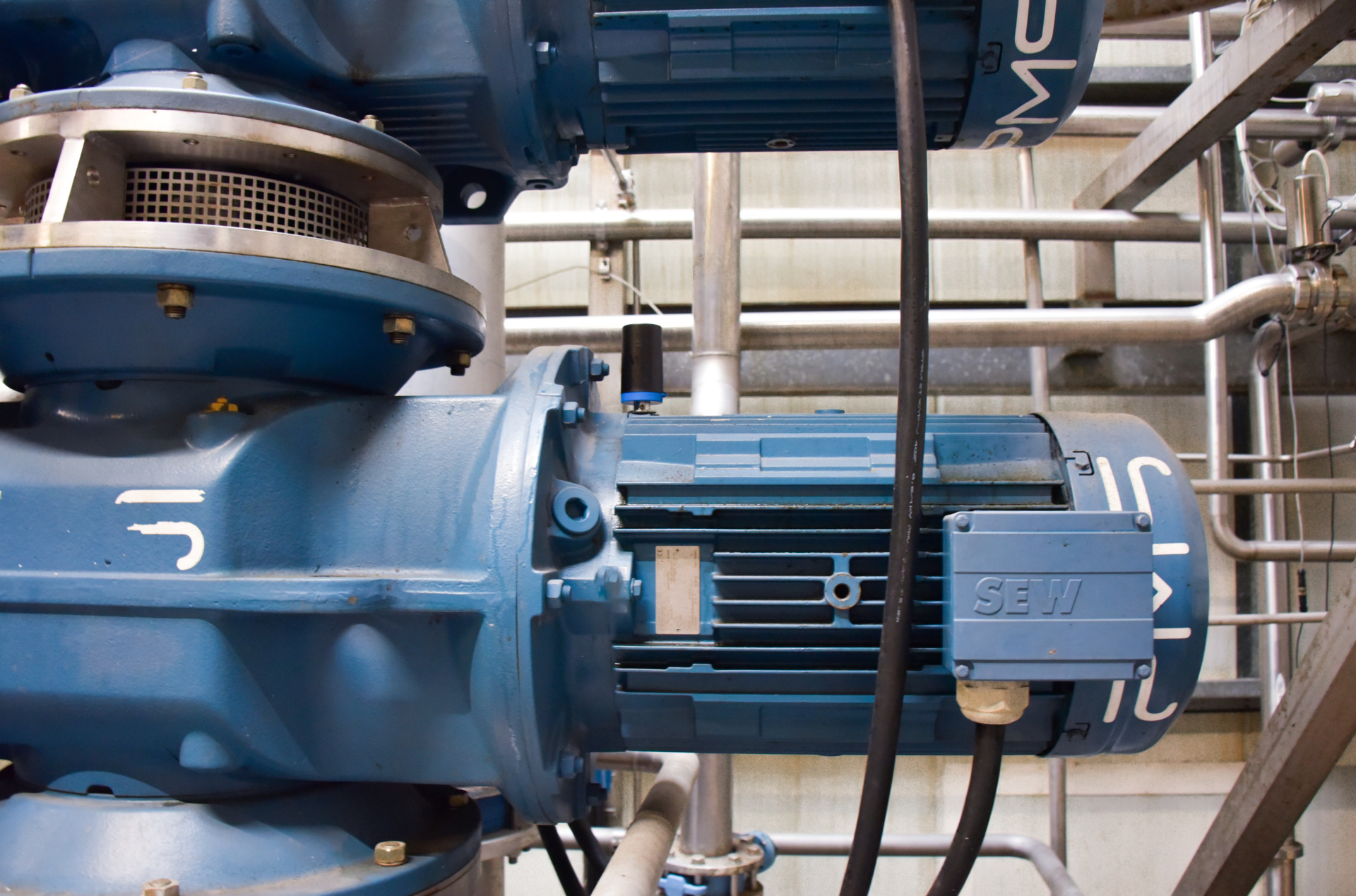

Vibration Analysis detects early problems and provides real-time responses to changing conditions in rotating machinery, including gearboxes, motors, fans, pumps, and shafts.

It is the most widely used technology today, allowing to take maintenance action before a failure disrupts operations.

What Can Vibration Analysis Monitor?

- Rotor imbalance

- Wheel imbalance

- Misalignment

- Soft foot

- Looseness

- Bearing defects

- Rolling element

- Outer/Inner race

- Lubrication issue

What Do Our Services Include?

Ready to Forget

About Asset Downtime?

Explore how vibration analysis can improve the efficiency of your rotating machinery and improve your production line efficiency.